LINEAR BEARINGS

Linear-motion bearings (aka linear slides) Linear-motion slides are designed to provide low-friction movement along one dimension. This is a very broadly-defined category of bearings, and can be further divided into two common types: rolling-element and plain bearings.

Linear slide bearings may be motorized, as with machine slides, XY tables, roller tables and some dovetail slides; or they may utilize inertia or hand-operation, as with non-motorized dovetail slides, ball bearing slides and roller slides. Certain advanced types of linear-motion slides may be designed to provide movement over more than one axis.

Ball bearing slides (aka ball slides)

Most linear motion slides are crafted as ball bearing slides. Noted performance characteristics are: extremely precise motion along one axis, self-lubrication ability, extreme durability. Ball bearing slides are most commonly used in precise instrumentation or delicate machinery, including applications involving aerospace, aviation, robotics, general manufacturing, and many more.

Lightweight aluminum is adequate for many ball slides, but hardened, stainless, or galvanized steel is generally preferred for improved reliability. Ball bearing slides are comprised of a base of twin lines of ball bearings arrayed on opposite sides, and a carriage that rides above. They can be used in motorized or non- powered equipment. Wear & tear is an issue, and most ball bearing slides are not appropriate for heavier loads.

Roller slides bearings (aka crossed roller slide bearings)

Roller slides are derived from linear roller bearings and provide low-friction/low-speed linear movement, typically for non-motorized equipment. Criss-cross orientation delivers improved performance for heavy loads and movement control. These linear slide bearings are adjustable, making them perfect for applications that demand a versatile platform. Roller slides bearings are preferred in a wide variety of industries, including manufacturing, aerospace, telecom, medical, and many others. Roller slides bearings are frequently found on equipment in clean rooms and vacuum environments.

Roller slides bearings are comprised of a moving carriage atop a stationary base. The action is similar to that of traditional ball bearings, differing only in bearing shape – cylindrical versus spherical. For criss-cross mounts, the angle is set at 90° for optimum efficiency. The bearing raceways are 'V-grooved', with one on each of the carriage and base – an end cap provides an absolute limit to the movement of the carriage. Lightweight aluminum is preferred for the carriage, hardened steel for base and end cap.

More exotic linear motion slides incorporate stack-able slides and/or double carriages, to allow linear movement through more than one axis. As with all linear slide bearings, the contact patch is linear rather than a single point – this allows heavier loads and decreases erosion. Roller slides bearings are noted for their endurance and ability to maintain good performance characteristics even in challenging environments, such as those that include airborne contaminants. However, they are not considered self-cleaning.

Rolling-element bearings

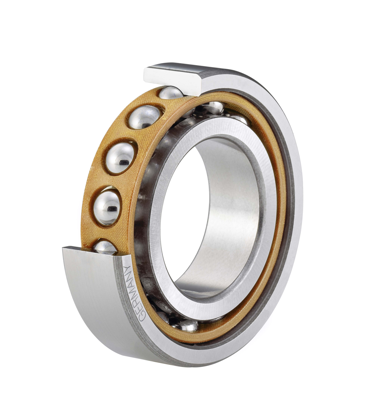

Rolling-element bearings are a unique and technically-advanced design that can be made as either ball bearing or roller slides. These linear slide bearings feature an outer ring, fashioned like a sleeve, that houses one or more rows of ball bearings that are held in place by cages. Rolling-element bearings are generally low-cost over lifetime and performance characteristics are: exceptional durability, low maintenance, and smooth low-friction movement.

Rolling-element bearings are quite rigid and require hardened or stainless steel raceways. These linear slide bearings require seals and lubrication, and are not appropriate for use in environments that include exposure to airborne contaminants.

Plain bearings These are a variant of rolling-element bearings that do not use ball bearings – instead, they utilize raceways. In comparison to roller-element bearings, plain bearings demonstrate added flexibility, do not require lubrication or seals, sustain performance in a larger thermal range, and are more tolerant of contaminants. Plastic and aluminum plain bearings are softer and more flexible, while the steel models offer more durability.

Dovetail slides (aka dovetail way slides)

These linear motion slides are typically crafted from stainless steel, cast-iron, or hardened aluminum. Dovetail slides derive their name from the 'V-shaped' channels on the bearing's carriage and base – this channel architecture guides the carriage's linear movement, allowing free movement along that axis. A 'dovetail table' is created when a platform is attached to the carriage, and this configuration allows for enhanced load-bearing performance.

Dovetail slides have a much greater surface area than other similarly-sized bearings – this results in additional friction and the need for more force to be used in order to initiate and accelerate the carriage. For some applications, trading friction for load capacity is an easy one to make and these linear slide bearings are widely used in shuttle devices, work-holding devices, CNC machines, and more.

Other notable performance characteristics include: enhanced shock resistance & durability, steady performance in dirty conditions, and flexibility in drive profile (dovetail slides can be motorized, mechanical or electromagnetically). Because of their design, dovetail slides are not used in applications that demand a high level of precision.