Ball Bearing - Cylindrical Roller Bearings

About

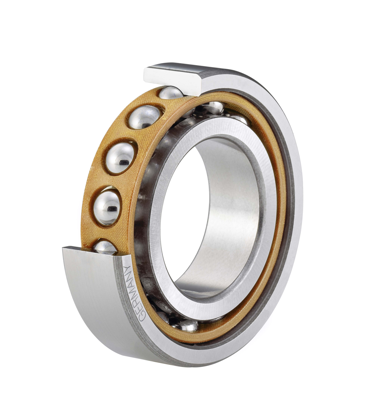

Rolling bearings are designed to carry loads by placing rollers or balls between the inner and outer bearing rings of the apparatus, thus providing a smooth sliding mechanism with very little resistance. The advantage of cylindrical ball bearings lies in the utmost optimization of weight, cost, load-capacity and durability. Cylinder ball bearing rollers are characterized by their particular design in which cylindrical rollers as opposed to balls are used as rolling mechanisms, maximizing the radial load capacity and performance speed. Ball bearing rollers are particularly designed to carry large quantities of radial loads at a relatively high speed. However, this often comes at the cost of a frictional increase. Find more about cylindrical roller bearing applications in our blog.

Engineering & Design

The ball bearing rollers are carefully designed to distribute loads across the surface area via linear contact with the mechanism's outer ring. The rollers thus glide onto the raceways and allow for axial movement with the assistance of ribs placed either on the inner or outer rings, depending on the selected model. The increase in number of ball bearing rollers is directly correlated with an increase in the mechanism's performance speed.

The rings and rollers are often made from alloy steel in order to yield maximum durability. In order to hold a high acceleration speed and strong carrying capacity, these types of bearings are most typically supplied with a pressed steel or machined brass cage (although polyamide cages are also available in selected models).

Ample Range of Model Availability

Roller cylindrical ball bearings are available in a number of different models and configurations with a range of cage designs, dimensions, and side rib applications. Cylindrical roller bearing types are classified according to the following categories:

Single-Row roller cylindrical ball bearings - These have a single caged cylindrical roller bearing. They are typically available in different models, with or without side ribs, engineered to accommodate for multiple applications. Single-row rolling bearings are typically sub-categorized into N, NU, NJ, NF, NP, and NUP designs. The difference between these classifications lies primarily in the number and location of the side ribs. These contribute to the speed and amount of friction exerted at the time of usage.

Double-row cylindrical roller bearings: These have an augmented strength and radial capacity due to their double-row configuration. These two-row cylindrical ball bearings are highly rigid and are mainly used for precision machine tools. Double row cylindrical roller bearings are typically sub-categorized into NN and NNU models. The difference between these designs lies primarily in the number and location of the side ribs, which contribute to the speed and amount of friction exerted at the time of usage.

Multi-row Cylindrical roller bearings - These are built with four or eight roller rows, and are advantageous due to their high radial load capacity, yet lag behind other models in their thrusting capacity. They are primarily aimed at the metal rolling industry due to their ability to carry heavy loads of steel, aluminum and other rolling mills.

Haven't found what you want? Use our bearing finder, or look here