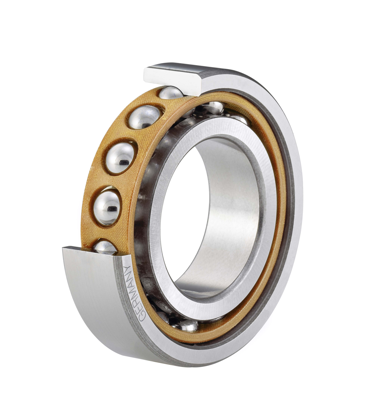

Angular Contact Bearings

About

Thin section bearings, often referred to as "constant section" (CS) bearings are distinguished from conventional standardized ISO ball bearings due to the particularly optimal characteristics of their cross-section. The uniqueness of thin section ball bearings lies in their outstanding performance in spite of weight and space limitations. Their miniscule, typically squared cross-section allows for the mechanism's high-precision.

Engineering & Design

Thin ball bearings are highly-efficient yet compact mechanisms designed with a minimal width and external diameter. The cross-section is typically double the ball's diameter, and the difference in dimensions between the inner and outer rings is thus optimally diminished. In order to efficiently reduce the friction and vibration while the ball bearing is at work, the raceways are given a polishing finish yielding a super-smooth external surface and are loaded with high-quality balls in order to maximize performance.

These ball bearings are typically offered in both stainless steel and chrome steel. The former provides the advantage of a prominent ability to adapt to various temperatures and is resistant to oxidation, while the latter holds temperature limitations, yet is advantageous due to its external oil-coating protective finish. Both of these allow the mechanism to function in both corrosive and non-corrosive environments.

Thin ball bearings are available in a variety of models including four point contact bearings, angular contact bearings and deep groove ball bearings; in each model, the balls and cross-sections are adjusted to match the particular design while retaining the necessary thin ball bearing classifying qualities. While deep groove and four point contact ball bearings support both radial and dual-direction axial loads, angular contact ball bearings have a considerably higher support system due to their 30° contact angle and more augmented capacity (fitting a larger quantity of balls).

Advantages & Benefits

As suggested by the name, thin ball bearings were designed to provide an effective solution for the demand for ball bearings under difficult space restrictions. While thin bearings may not be utilized for heavy-duty industrial purposes, an ample range of load-capacities are offered and the ball bearings' availability in a myriad of cross-section sizes serves multiple purposes. Additionally, the light-weight design accurately reduces friction and performs with the utmost, concise precision.

Applications

Due to their thoroughly thought out design, thin ball bearings are used in a variety of fields: robotics, solar panels, radar and microwave devices, guidance systems, measuring systems, medical equipment, semiconductor equipment, the aerospace industry, among many others.

Haven't found what you want? Look here